AFP (Advanced Formed Parts) are engineered components that can be manufactured with the core Agrati Group technology; the cold forging process.

IN THIS SECTION

There are 4 main features that define what an AFP is: complex geometry, tight tolerances, alternative materials, advanced processes.

COMPLEX GEOMETRY

Our extensive expertise in the cold forging process allows us to obtain complex geometries with high production rate, yet minimize scrapped material, and this allows Agrati to provide a competitive price compared to other manufacturing technologies.

TIGHT TOLERANCE

Engineered components usually requires tight tolerance. For this reason, the production process of an AFP involves further integrated machining operations such as turning, grinding, drilling, rolling.

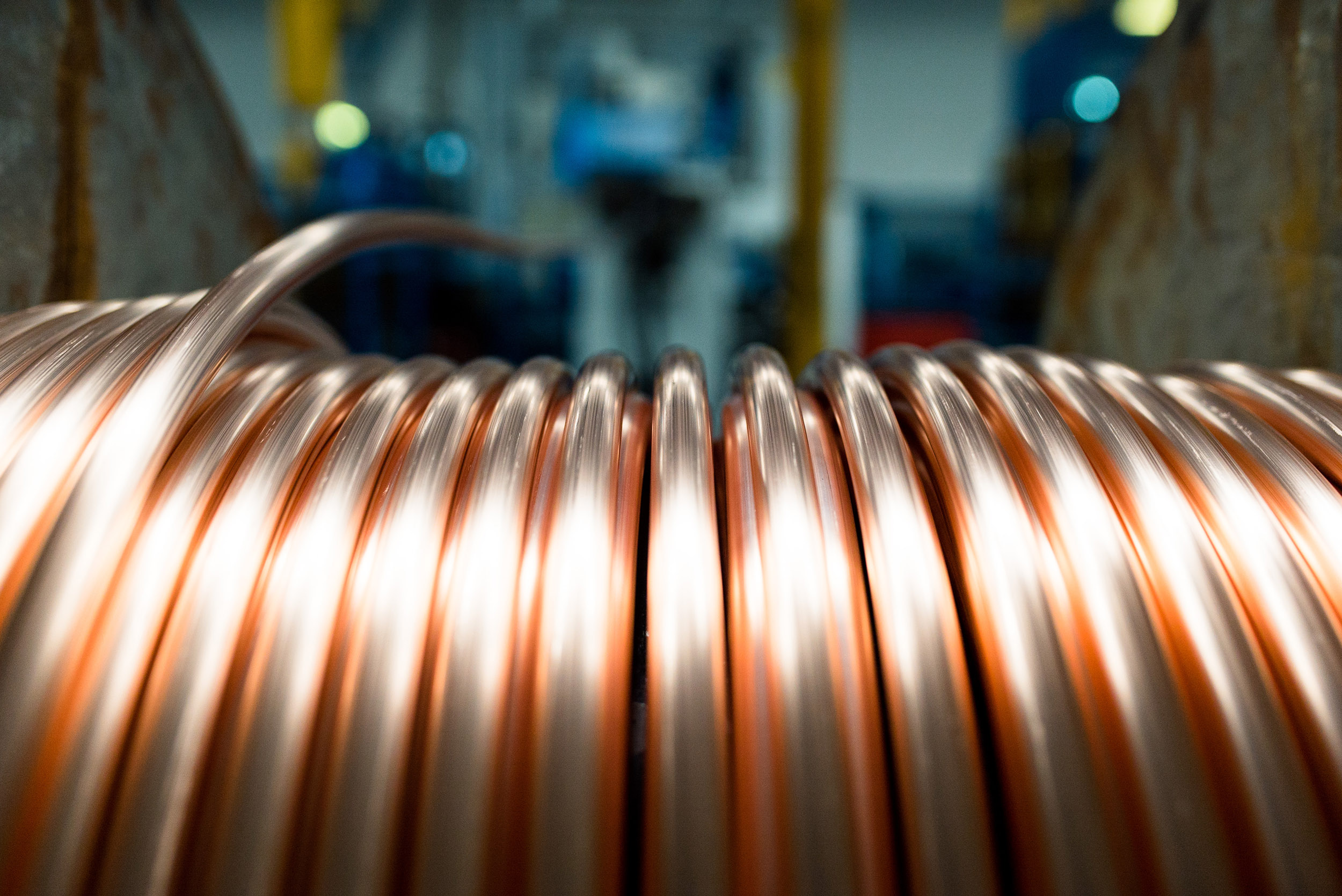

ALTERNATIVES MATERIALS

In some cases, an AFP is made of special metals different from carbon steel (like stainless steel, copper, aluminum…). It can also be overmoulded with plastics or assembled with other metal or plastic components.

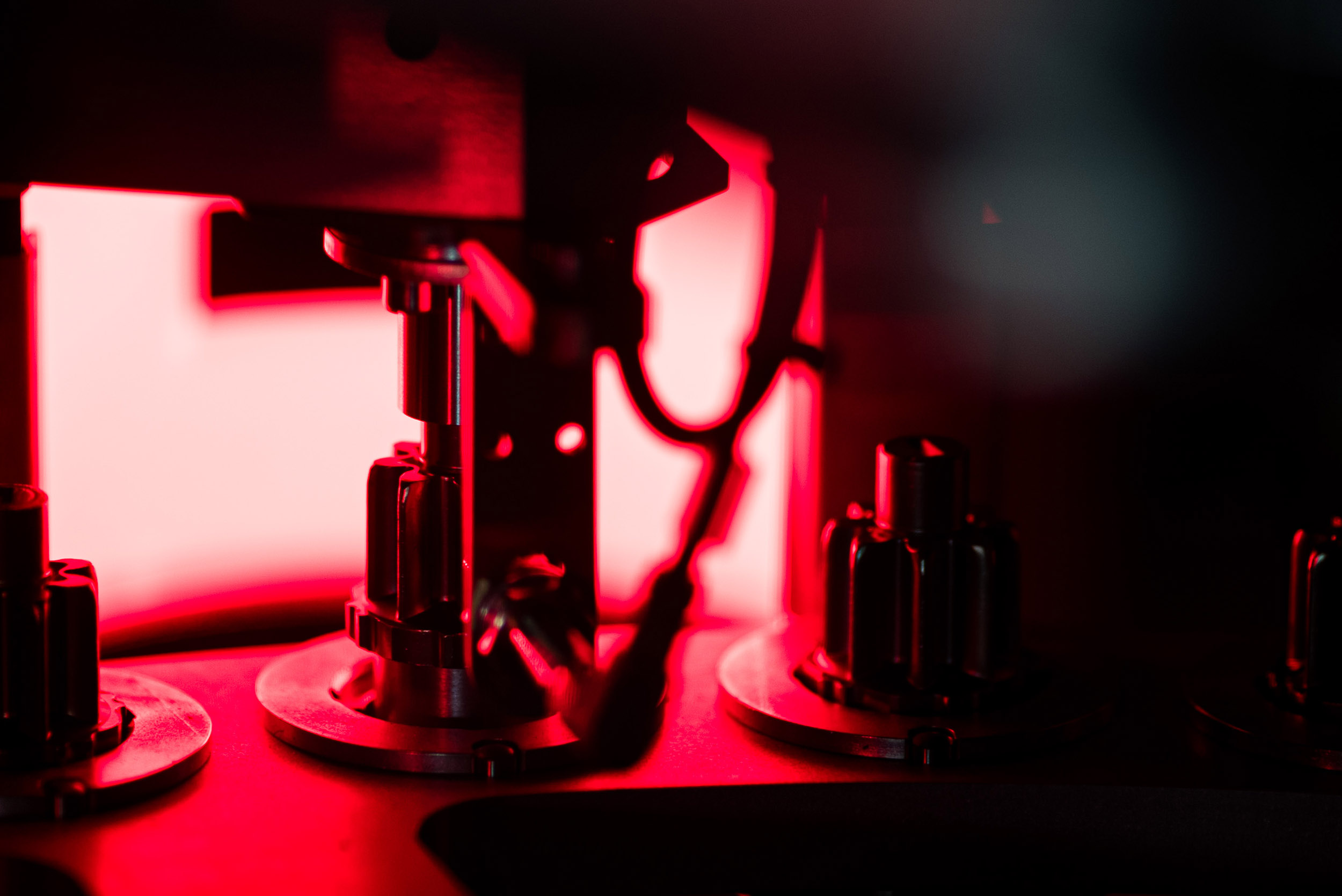

ADVANCED PROCESSES

Automated assembly lines guarantee the production of high volumes demanded in the automotive market.

These parts are used in several fields of automotive applications: chassis, seatings, brakes and safety systems, engine, powertrain & driveline systems. These are products manufactured according to strict customer specifications.

Dedicated control plans during production and the ability to do 100% sorting before packaging guarantee the complete fulfilment of quality requirements.

With the experience gained over the years, Agrati Group is a proven partner in designing and validating these complex parts, starting from the proposal drawing to the final functional test on real applications, passing through the Finite Element Analysis and the prototype manufacturing.