The electrification trend is shaping the future of mobility.

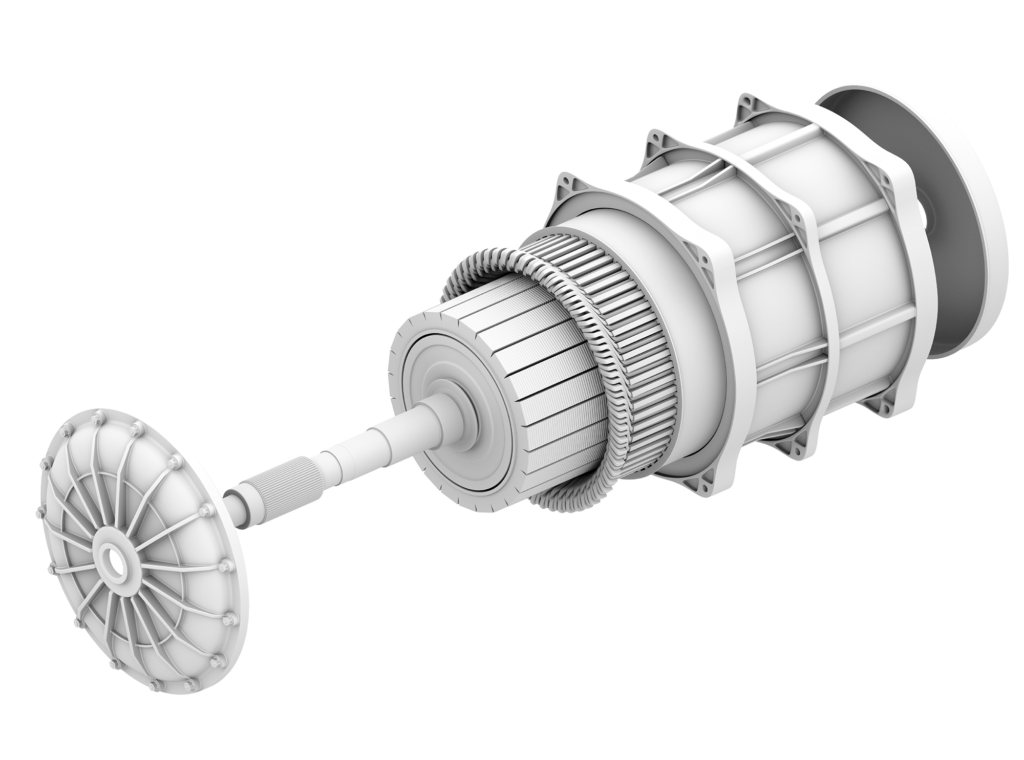

Following the evolution of the market, in recent years Agrati has pursued a development of products strongly focused on electrified vehicles.

Agrati has built expertise in creating bolts for electric vehicles, developing a dedicated design, consisting of long bolts and tie rods.

Agrati’s offer also includes the use of special materials for electronic applications due to their electrical conduction capabilities.

In other applications, electrical insulation requirements suggest the use of engineered plastics, which are part of Agrati’s knowledge and offer, also combined with cold forged metal parts.

In addition, electric vehicles require sealing properties for their bolts to ensure the safety of their battery pack, as well as the cleanliness of the products, to guarantee the control of particulate contamination and to maintain the correct operation of electronic & high voltage components.